Industrial Coffee Grinder: Finding the Best Choice for Your Shop

Industrial Coffee Grinder: Finding the Best Choice for Your Shop

Blog Article

Industrial Coffee Grinder Guide: Boost Performance and High Quality

In the competitive landscape of coffee manufacturing, choosing the ideal industrial coffee grinder plays a pivotal role in boosting both efficiency and item high quality. Comprehending the nuances of numerous mill kinds and vital functions-- such as adjustable grind setups and robust building-- can considerably influence the final flavor profile of the coffee. Furthermore, the optimization of the grinding process, coupled with attentive upkeep, is necessary for sustaining performance in time. As we explore these important components, it comes to be obvious that the ramifications extend past simple equipment option, influencing total business success in methods that require closer evaluation.

Recognizing Grinder Kinds

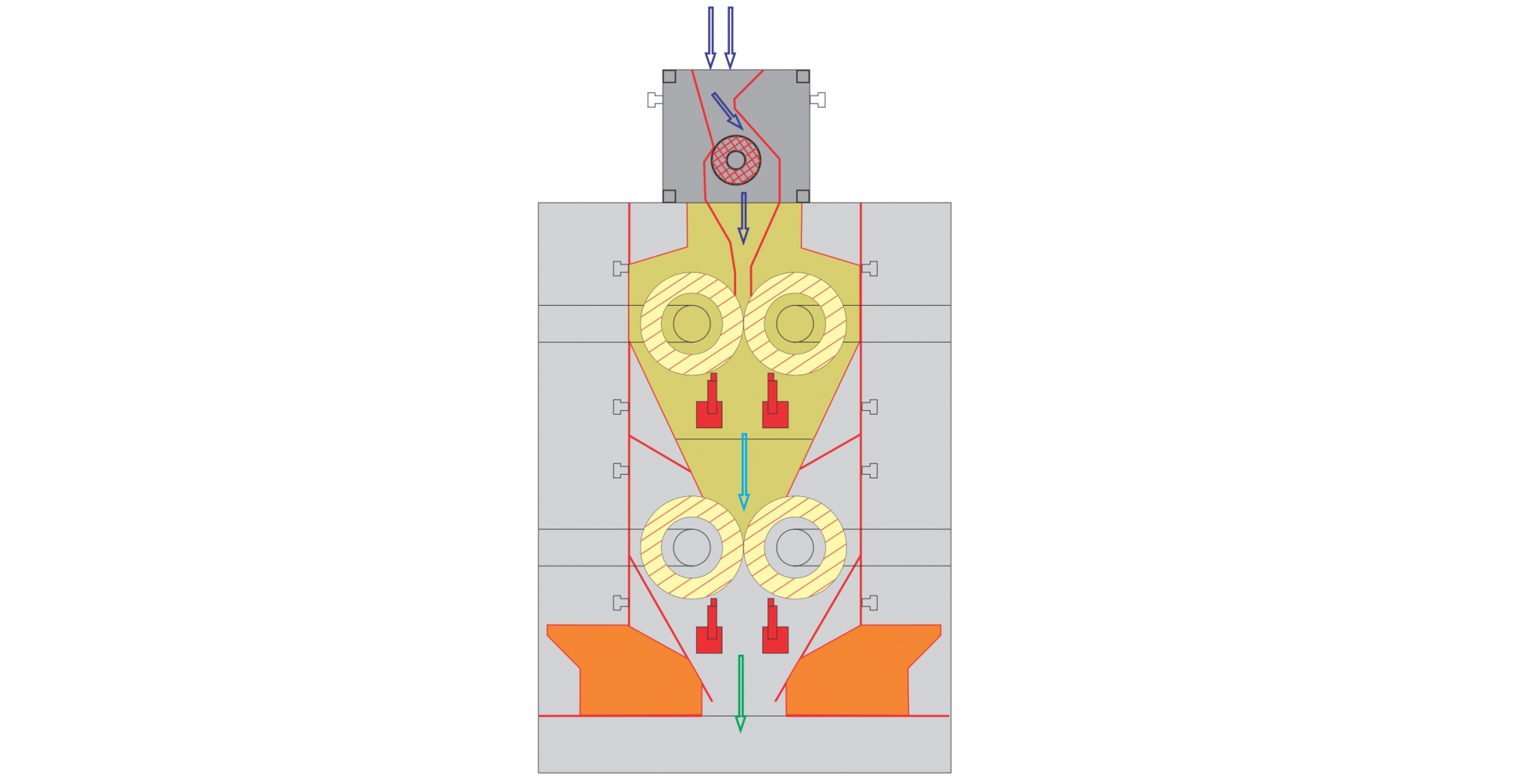

When picking an industrial coffee grinder, recognizing the different kinds available is essential for enhancing both taste removal and operational efficiency. The 2 key sorts of mills are blade grinders and burr grinders. Blade grinders utilize sharp blades that chop coffee beans into inconsistent sizes, causing unequal extraction and potentially unfavorable flavors. While blade mills are commonly extra budget friendly and suitable for small-scale procedures, they are usually not suggested for commercial use.

Ultimately, picking the ideal sort of mill is essential to maintaining top quality and efficiency in coffee manufacturing, making it critical for organizations to invest in top notch burr mills for optimal outcomes.

Key Features to Think About

Selecting an industrial coffee mill calls for careful factor to consider of a number of essential functions that can significantly influence both performance and the total coffee experience. Among the primary facets to assess is the grinding device. Burr mills are normally chosen over blade grinders, as they supply a consistent grind size, which is important for optimum removal and taste.

Another vital feature is the mill's capacity. A functional mill with numerous setups enables you to tailor the grind dimension to various developing techniques, enhancing the coffee's flavor account.

The construction product likewise plays a role in toughness and upkeep. Stainless steel elements usually supply long life and are easier to clean, which is important for keeping health standards. Lastly, assess the grinder's sound degree, specifically in a hectic coffee shop or production environment, where excessive sound can be disruptive. Investing in a mill that balances these functions can significantly boost both functional efficiency and the top quality of the coffee offered.

Optimizing Grinding Refine

To accomplish the finest outcomes in coffee prep work, optimizing the grinding process is crucial. The grind size substantially affects removal, flavor, and overall top quality of the made coffee.

Additionally, keeping track of the grinding rate can optimize the process. Slower grinding usually generates much less heat, preserving delicate flavors and imp source aromas. Conversely, quicker grinding may produce extreme warm, negatively influencing the coffee's top quality.

Maintenance and Care Tips

Correct upkeep and care of industrial coffee grinders are important for making sure optimal performance and longevity. Regular cleansing is the structure of upkeep; residue accumulation can impact flavor and grinding performance. It is suggested to clean the mill after each use, wiping down the exterior and getting rid of any type of coffee grounds from the burrs.

Additionally, inspect the grinding burrs for wear and tear. Plain burrs can endanger work consistency, so they should be changed as essential. Industrial Coffee Grinder. Periodically calibrating the mill is likewise important, as this preserves the preferred work size for different developing techniques

Lubrication of moving parts should be executed according to the maker's specs, as this reduces rubbing and extends the life of the devices. It is vital to utilize food-grade lubes to ensure safety and compliance with health and wellness policies.

Last but not least, keep the mill in a secure and dry setting to stop corrosion and corrosion. By sticking to these maintenance and treatment suggestions, drivers can improve the efficiency of their industrial coffee grinders while ensuring high-grade outcome and expanded functional life.

Roi Evaluation

Evaluating the roi (ROI) for commercial coffee grinders is critical for businesses seeking to enhance their coffee manufacturing capabilities. A detailed ROI analysis helps figure out the monetary stability of purchasing high-quality grinders, allowing companies to weigh the preliminary prices versus possible gains.

Assess the purchase rate of the grinder, including installment and any type of required modifications to existing framework. High-performance mills typically lead Read More Here to reduced grinding time and raised throughput, which can considerably enhance performance.

Furthermore, consider the effect on product quality. Industrial Coffee Grinder. Superior grinders yield an even more consistent work size, which can enhance flavor profiles and client satisfaction, eventually driving sales. By raising the high quality of the final item, businesses can validate greater prices, leading to boosted revenue

Verdict

In recap, a commercial coffee mill plays a critical role in improving both effectiveness and product high quality within coffee production. Eventually, the calculated financial investment in a trustworthy mill contributes dramatically to boosted earnings and competition in the coffee sector.

In the competitive landscape of coffee manufacturing, choosing the ideal industrial coffee grinder plays a crucial duty in improving both performance and item high quality. The two key kinds of mills are blade grinders and burr mills. Within the burr mill classification, there are flat burr mills and conelike burr mills, each with its benefits. Burr grinders are typically favored over blade grinders, as they offer a regular grind dimension, which is vital for optimum removal and flavor.

In summary, an Going Here industrial coffee grinder plays an essential role in enhancing both effectiveness and item quality within coffee manufacturing.

Report this page